The interferometer is a universal length measuring tool that measures the displacement using a Michelson interference system with a known laser wavelength. Laser interferometers are available in single frequency and dual frequency. The single frequency appeared in the mid-1960s and was originally used to characterize the reference line scale and then used to accurately measure length in the metering chamber. The dual-frequency laser interferometer appeared in 1970 and is suitable for use in the workshop. The laser interferometer has a high measurement accuracy at a very close standard (temperature 20 ° C, atmospheric pressure 101325 Pa, relative humidity 59%, CO2 content 0.03%).

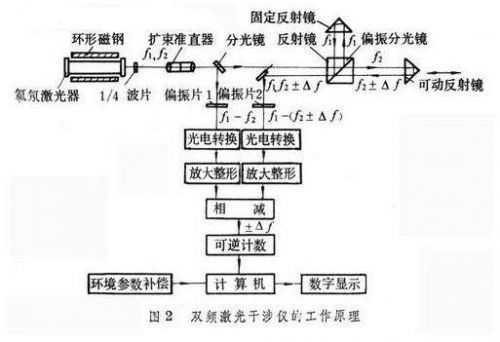

Figure 1 shows the working principle of a single-frequency laser interferometer. The beam emitted from the laser is split by the beam splitter and split into two paths by the beam splitter, and reflected from the fixed mirror and the movable mirror respectively to merge with the beam splitter to generate interference fringes. When the movable mirror moves, the change of the intensity of the interference fringes is converted into an electrical pulse signal by the photoelectric conversion element and the electronic circuit in the receiver, and after being shaped and amplified, the input of the reversible counter is used to calculate the total number of pulses, and then the electronic computer is used. Calculated according to the following formula![]()

In the formula, λ is the laser wavelength (N is the total number of electric pulses), and the displacement L of the movable mirror is calculated. When using a single-frequency laser interferometer, the surrounding atmosphere is required to be in a stable state, and various air turbulences will cause a change in the DC level and affect the measurement result.

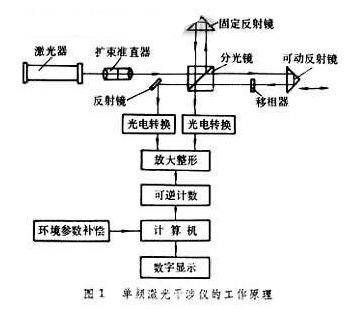

Dual frequency laser interferometer

Figure 2 shows the working principle of a dual-frequency laser interferometer. On the HeNe laser, an axial magnetic field of about 0.03 Tesla is added. Due to the Zeeman splitting effect and the frequency pulling effect, the laser produces two different frequencies of left and right circularly polarized light of 1 and 2. After 1/4 wave plate, it becomes two mutually perpendicular linearly polarized lights, and then split into two paths through the beam splitter. After passing through the polarizing plate 1, it becomes a reference beam having a frequency of f1 - f2. The other path is divided into two paths by the polarizing beam splitter: one path becomes a beam containing only f1, and the other path becomes a beam containing only f2. When the movable mirror moves, the beam containing f2 is reflected by the movable mirror to become a beam containing f2 ± Δf, and Δf is an additional frequency due to the Doppler effect when the movable mirror moves, and the sign indicates movement. Direction (Doppler effect is proposed by Austrian CJ Doppler, that is, the frequency of the wave changes when the wave source or receiver moves). This light beam and the light beam reflected by the fixed mirror and containing only the light of f1 pass through the polarizing plate 2, and are combined into a measuring beam of f1 - (f2 ± Δf). The measuring beam and the reference beam are subtracted from the respective photoelectric conversion elements, amplifiers, and shapers into a subtractor, and the output becomes an electrical pulse signal containing only ±Δf. After being counted by the reversible counter, the amount of displacement of the movable mirror can be obtained by equivalent conversion (by 1/2 laser wavelength) by an electronic computer. The dual-frequency laser interferometer uses the frequency change to measure the displacement. This displacement information is carried on the frequency difference between f1 and f2, and is insensitive to the change of the DC level caused by the change of the light intensity, so the anti-interference ability is strong. It is often used to verify the coordinate accuracy of length measuring machines, coordinate measuring machines, lithography machines and machining centers, and also as a measuring system for length measuring machines and high-precision coordinate measuring machines. High-precision straightness measurement, flatness measurement and small angle measurement are also possible with the corresponding accessories.